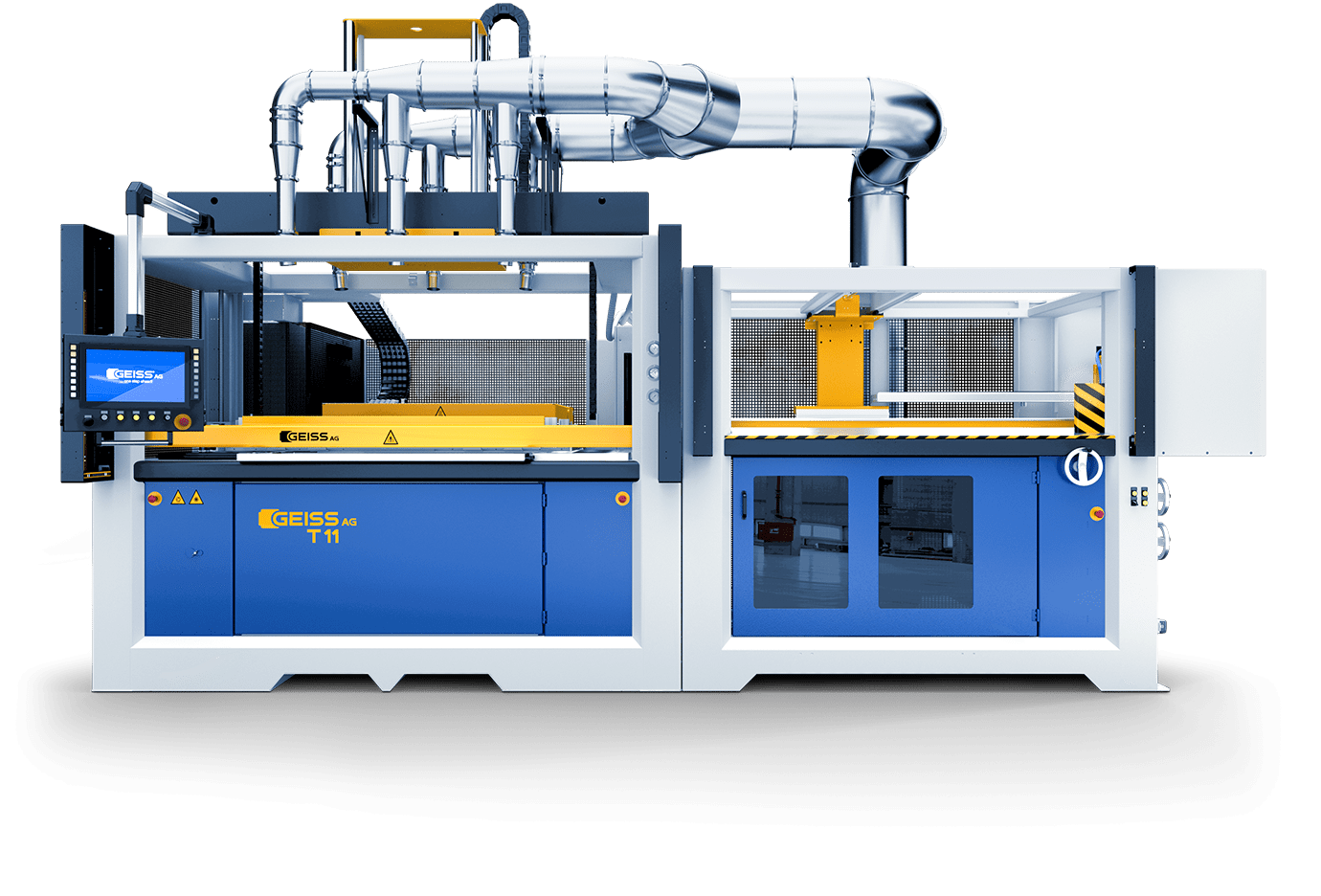

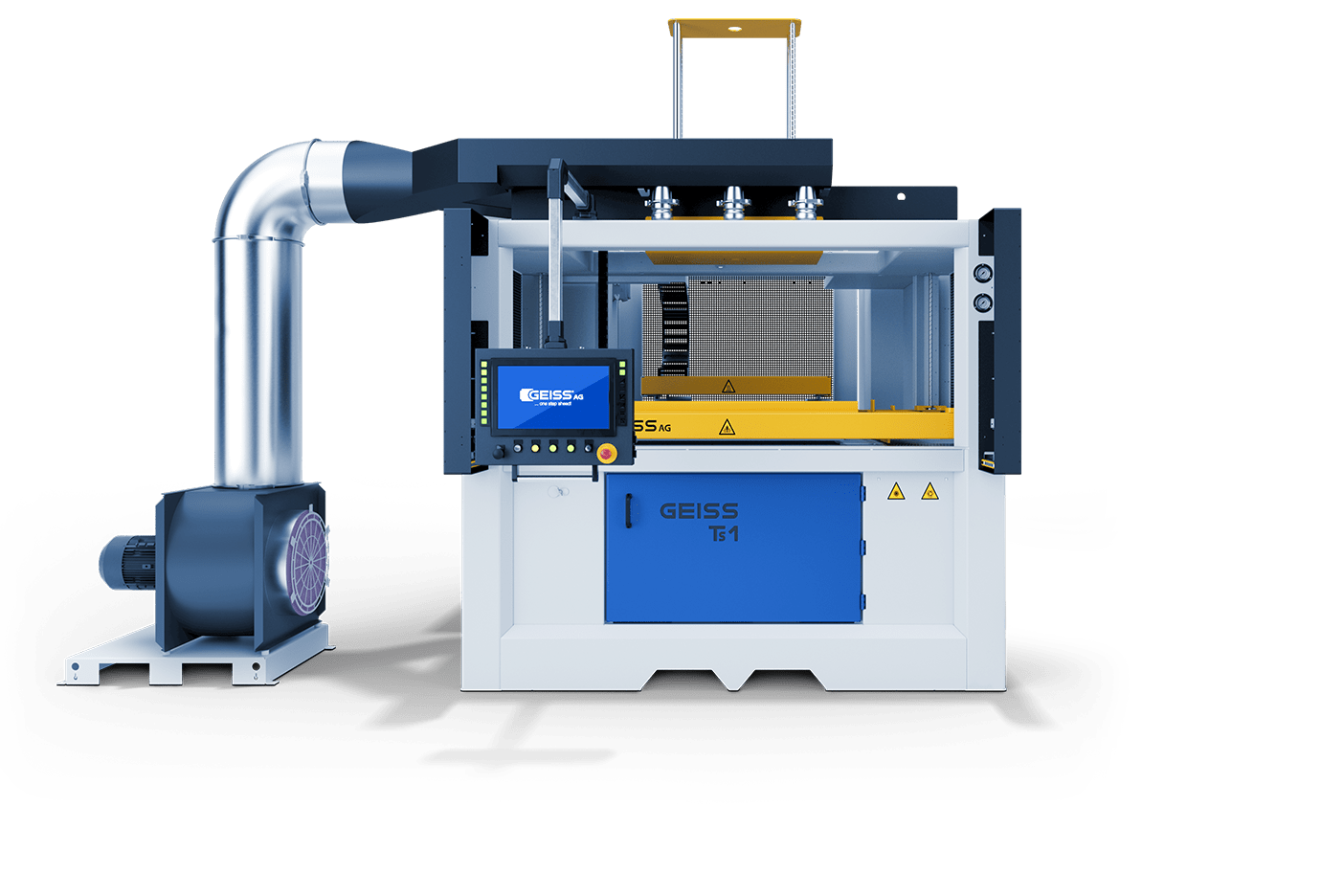

Thermoforming Technology

Our thermoforming systems are guaranteed to process any thermoplastic new product with any material thickness within the material specifications.

For more information about our thermoforming systems, call us at (860) 605-8643 or complete the form.

Why Choose Us

Over 75 Years of Industry Experience

Long-Term Cost Saving Investment

Lowest Cost Per Part Produced

Optimized Operational Efficiency

Substantial Savings in Energy Consumption

Reduced Material Usage & Lowest Scrap Rate

Highly Customizable Solutions

Professional Service & Support

Frequently Asked Questions

What capabilities do Geiss, LLC thermoforming systems offer?

Our Geiss, LLC thermoforming systems are equipped for a range of applications, offering precision molding for various materials, rapid prototyping, and high-volume production capabilities.

How does Geiss, LLC ensure quality in its thermoforming systems?

Quality is embedded in our design and manufacturing process, with each system undergoing stringent testing to meet high standards of performance and reliability.

Do Geiss, LLC thermoforming systems support custom mold designs?

Yes, our systems are designed to work with custom mold designs, enabling us to meet the unique specifications and creative requirements of our clients.