Check our Plastics Machinery & Manufacturing Magazine's article featuring the upgrades on the T11 machine.

Cutting-Edge Precision

Description:

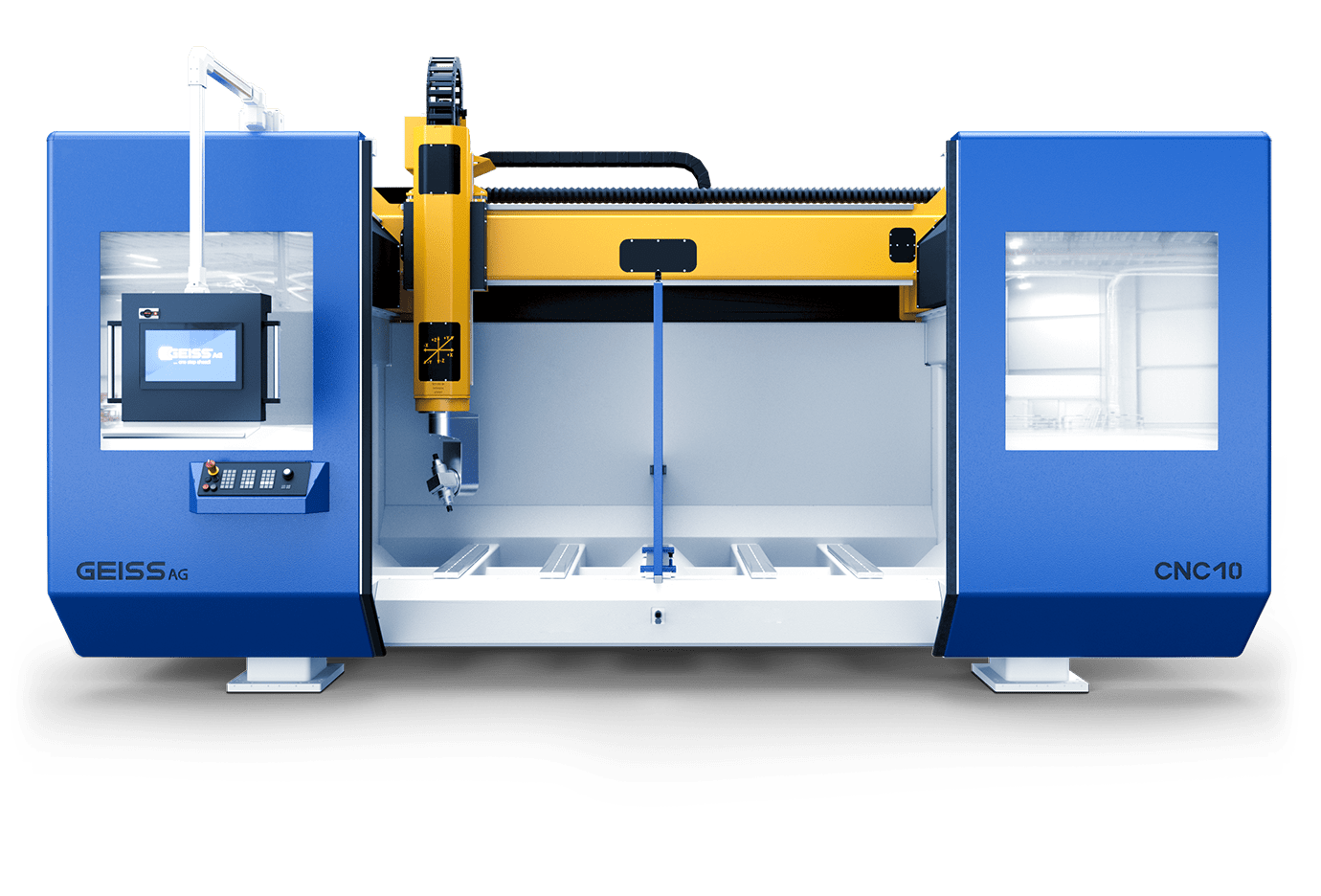

The Geiss, LLC CNC machining centers embody a fusion of advanced technology and user-focused design. These centers are engineered to deliver exceptional precision, facilitating intricate machining across a diverse spectrum of materials. Tailored to meet complex demands, they redefine the standards of accuracy and flexibility in the CNC machining space.

Advantages of Our CNC Machining Centers

Innovative Design

Our CNC systems embody cutting-edge engineering, offering customizable solutions that deliver efficient and precise machining. Designed with flexibility in mind, our systems adapt to your specific application requirements, allowing for scalable machine sizing and seamless integration into any production line. The result is high-performance machining at a competitive price, ensuring you get the most value for your investment.

Versatility in Appliance

With the capability to work with plastics, composites, model foams, and aluminium, our CNC centers are versatile powerhouses. They cater to diverse industry requirements, from prototyping to full-scale production.

Optimized Performance

Each machine is an epitome of performance, optimizing your production with speed and precision. The integration of state-of-the-art technologies provides a competitive edge, enhancing both quality and throughput.

Trimming Machine

The Speed King by Geiss

Experience the future of CNC trimming technology with the CNC10 ECO trimming machine: a fusion of unrivaled speed, precision and reliability.

Ultrasonic Trimming Machine

Versatile Cutting for Manufacturing

Features

Streamlined Workspace

The integrated machine table is crafted to maximize stability and precision, providing a robust foundation for all your machining tasks.

Enhanced Safety

With a focus on user safety, the system incorporates fail-safes and ergonomic design features to ensure secure operation during use.

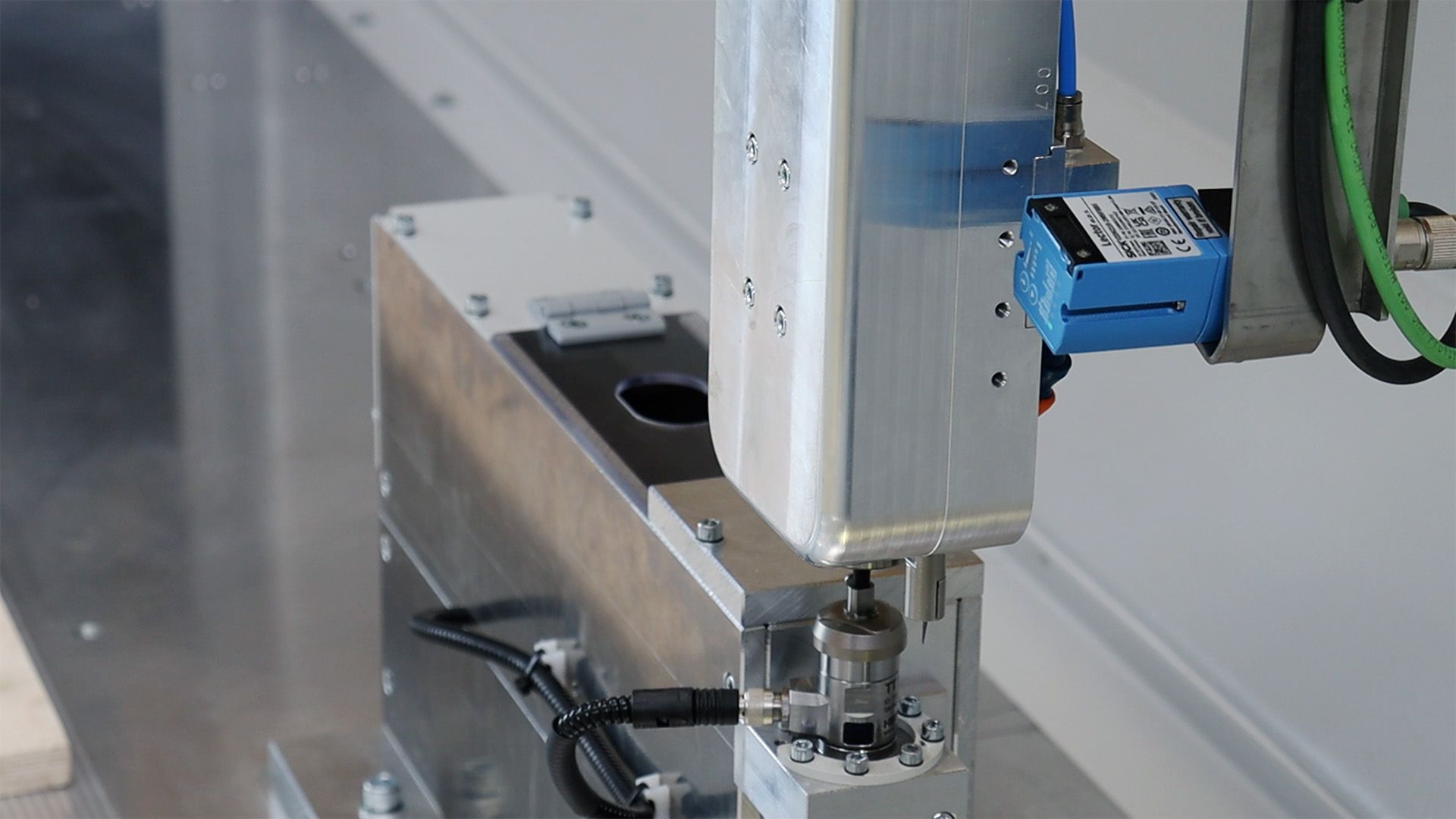

Innovative Control Technology

Harness the Siemens SINUMERIK ONE system, Geiss, LLC's choice for unparalleled precision and advanced control in CNC machining.

Dynamic Performance

Experience the smooth, rapid movements of Geiss, LLC's machinery, engineered for dynamic precision and reduced cycle times.

Enhanced Protection

Geiss, LLCmachines include shielding with bellows to protect critical components from debris and extend equipment longevity.

For more information about our ultrasonic cutting machine, call us at (860) 605-8643 or complete the form.

Why Choose Us

Over 75 Years of Industry Experience

Long-Term Cost Saving Investment

Lowest Cost Per Part Produced

Optimized Operational Efficiency

Substantial Savings in Energy Consumption

Reduced Material Usage & Lowest Scrap Rate

Highly Customizable Solutions

Professional Service & Support

Frequently Asked Questions

How do machine dynamics affect the performance of Geiss, LLC CNC centers?

Machine dynamics refer to the movement and stability of CNC machinery during operation. Geiss, LLC CNC centers are designed with optimized dynamics, meaning they operate smoothly and swiftly, ensuring high precision while minimizing vibration and wear. This results in more accurate cuts and a longer machine lifespan.

Why are shielding and bellows important in Geiss, LLC CNC machining centers?

Shielding and bellows are critical for protecting the mechanical and electronic components of CNC machines from contaminants like dust and metal shavings. Geiss, LLC utilizes these protections to prevent damage and wear, which maintains the precision of the CNC machining centers over time and ensures consistent, high-quality outputs.

Can Geiss, LLC CNC machines handle complex geometries?

Yes, our CNC machining centers are equipped with advanced control systems and dynamic tooling capabilities, enabling them to handle complex geometries with precision. They can produce intricate and detailed components that meet strict specifications.