Check our Plastics Machinery & Manufacturing Magazine's article featuring the upgrades on the T11 machine.

Unlocking Efficiency and Precision: How Our Geiss Thermoforming Machines Transformed a Customer's Process

How Upgrading to a Geiss Thermoforming Machine Reduced Material Costs by 25% and Enhanced Production Efficiency

In the fast-paced world of manufacturing, efficiency and precision are non-negotiable. Companies are constantly seeking ways to reduce costs, minimize waste, and enhance product quality. At Geiss LLC, we understand these challenges, and our advanced thermoforming machines are designed to meet them head-on. One of our recent case studies perfectly illustrates how upgrading to our technology can revolutionize a production process.

The Challenge: High Scrap Rates and Inconsistent Results

Our customer was struggling with a legacy vacuum-forming process that relied on an open chamber-style machine. This outdated technology led to several issues, including inconsistent results and an alarmingly high scrap rate. These problems were not just frustrating—they were costly. Material waste was piling up, and the company’s bottom line was suffering.

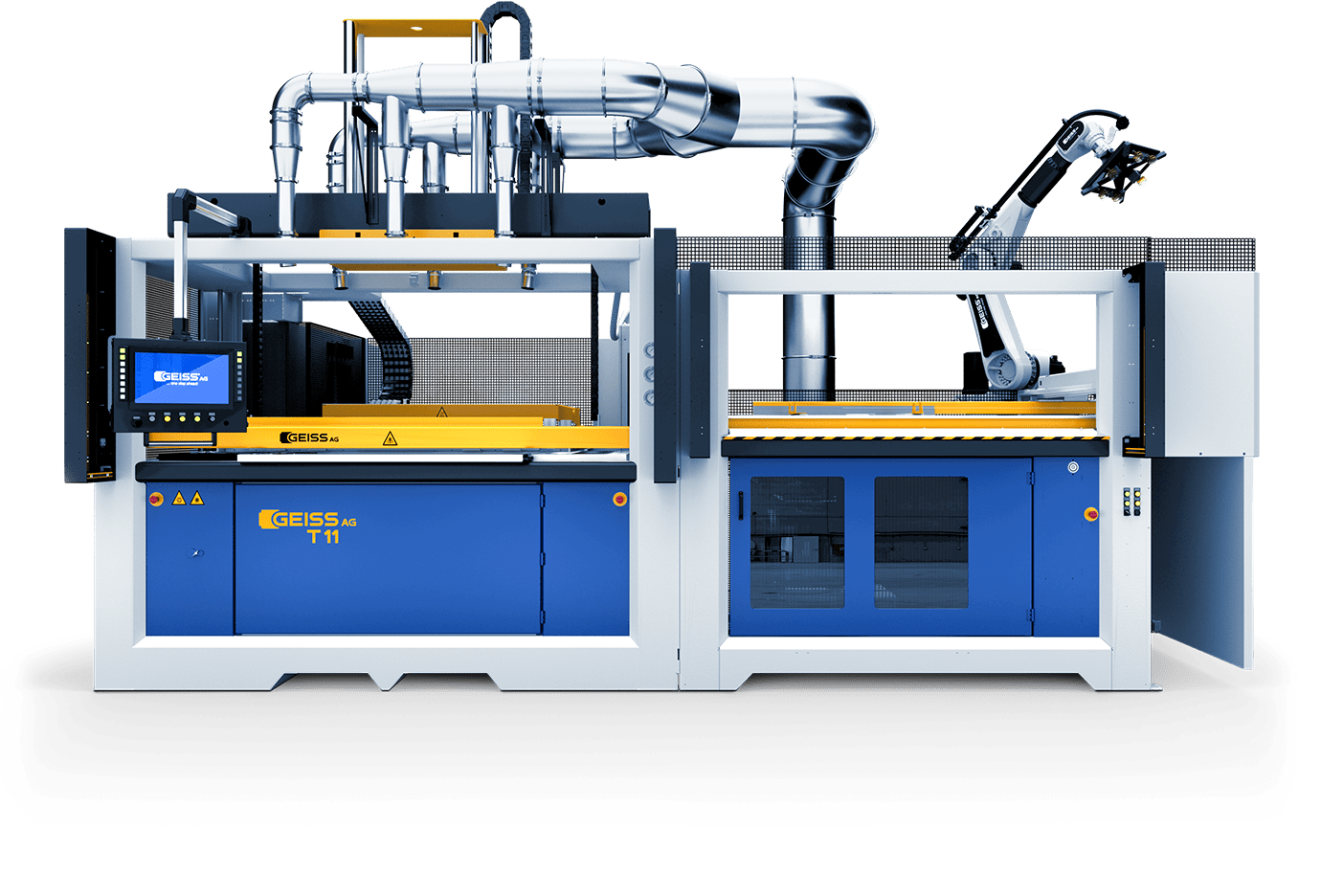

The Solution: A Geiss Thermoforming Machine

Upon receiving their first Geiss machine, the customer immediately noticed a dramatic improvement. The most significant change was the ability to reduce the overall sheet size by a few inches in both the X and Y directions. But that was just the beginning. The Geiss machine also allowed them to reduce the starting material thickness by an impressive 25%!

Why is this reduction so crucial? In thermoforming, 75% of the part cost is often tied to the raw material itself. By reducing the starting material thickness, our customer was able to significantly cut down on material costs without sacrificing the quality of the final product. In fact, the finish part geometry was not only maintained but improved, leading to better overall product quality.

Beyond Material Savings: A Holistic Improvement

The benefits of switching to a Geiss machine didn't stop at material savings. The customer also experienced a reduction in energy consumption—an average of 50% compared to traditional ceramic heating systems. This energy efficiency is not only good for the environment but also for the company’s operational costs.

Moreover, the scrap rate dropped dramatically, and changeover times were reduced, further streamlining the production process. The transition from their old vacuum-forming process to our Geiss machine led to a more repeatable, reliable, and efficient operation, solving the very issues that had been plaguing their production line.

A Proven Solution for Your Business

This case study is just one example of how our Geiss thermoforming machines can solve real-world manufacturing challenges. If you're facing issues with high material costs, excessive waste, or inconsistent product quality, it might be time to consider an upgrade. Our machines are engineered to deliver precision, reduce costs, and enhance the overall efficiency of your production line.

At Geiss LLC, we’re committed to helping our customers achieve their manufacturing goals. Whether you’re looking to reduce your raw material costs, improve product quality, or lower energy consumption, we have the solution.

Visit Geiss LLC to learn more about how our cutting-edge machines can transform your business.